Axis 1 : Hierarchical actuators for resilience

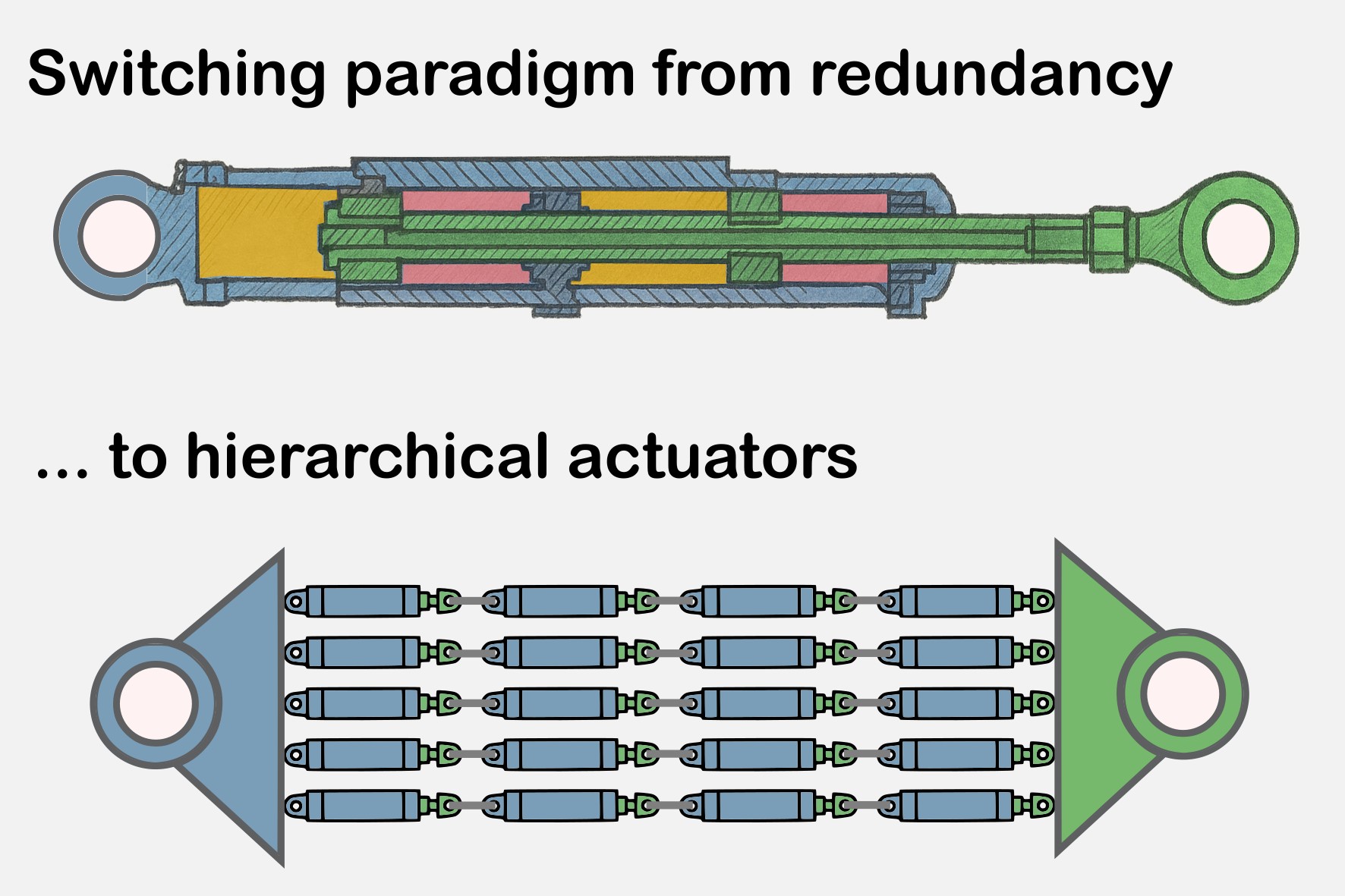

In industry, to ensure safety and reliability, critical actuators are designed with safety margins and are duplicated. In the event of a fault, a redundant actuator takes over. However, redundancy has drawbacks: it is expensive, it increases mass, resource consumption, energy consumption, and decreases autonomy. These constraints are significant for aerospace applications.

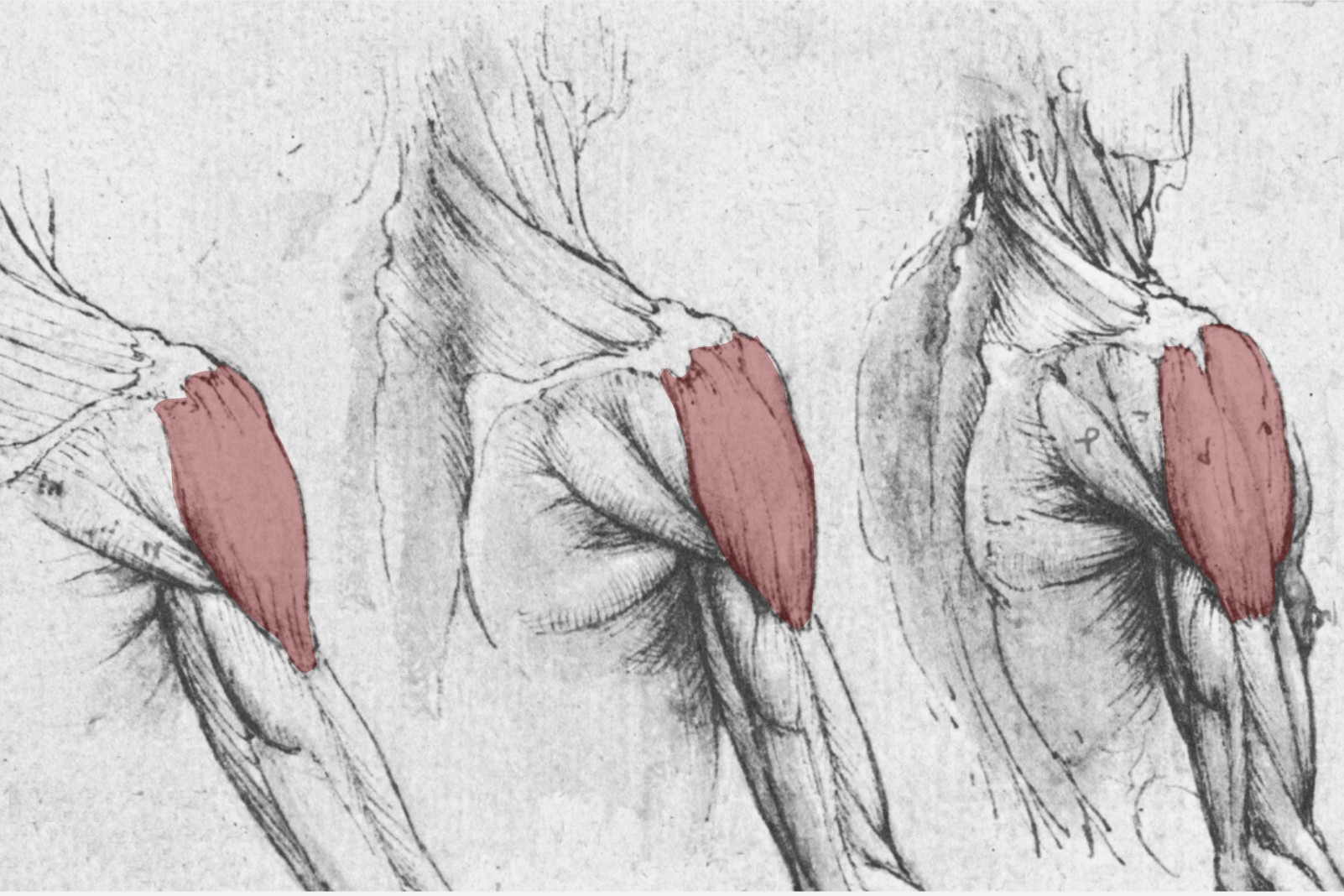

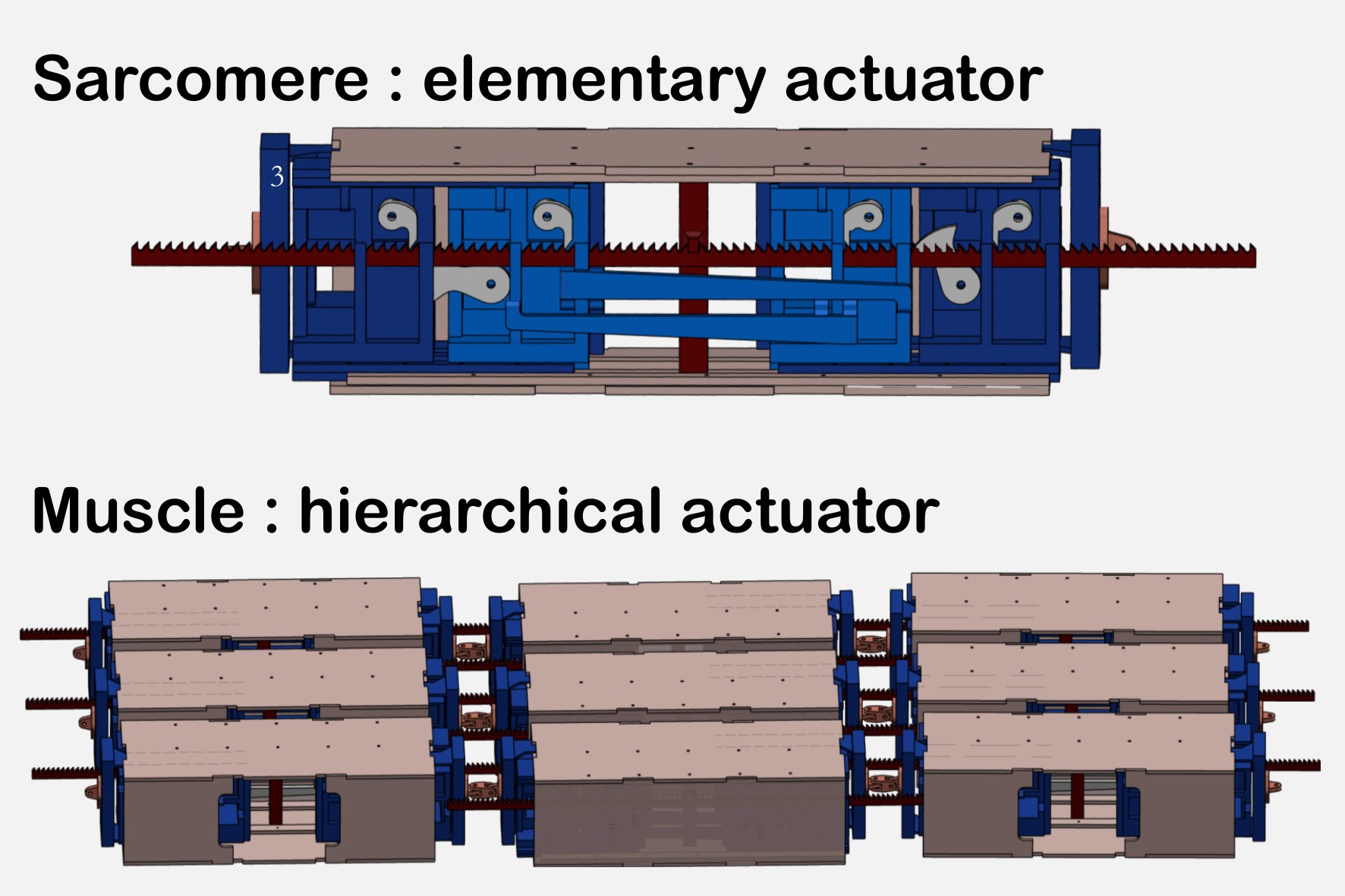

The current paradigm of actuator design (centralized action, monobloc, oversizing, complex servo control) does not allow breaking the limits of damage resilience. In contrast, biological actuators (e.g., skeletal muscle in animals, pulvinus in plants) have a decentralized architecture with multiple force paths, that makes them less sensitive to damage. This is the inspiration for our innovations with hierarchical actuators. Multi-degree-of-freedom actuators can adapt to micro-scale damage by distributing the load across neighboring actuators.

On a helicopter, for example, if the flight control actuator (blade orientation) begins to deteriorate with slight performance losses, a warning can be sent to the pilot to land for repair without threatening the integrity of the aircraft.

The current paradigm of actuator design (centralized action, monobloc, oversizing, complex servo control) does not allow breaking the limits of damage resilience. In contrast, biological actuators (e.g., skeletal muscle in animals, pulvinus in plants) have a decentralized architecture with multiple force paths, that makes them less sensitive to damage. This is the inspiration for our innovations with hierarchical actuators. Multi-degree-of-freedom actuators can adapt to micro-scale damage by distributing the load across neighboring actuators.

On a helicopter, for example, if the flight control actuator (blade orientation) begins to deteriorate with slight performance losses, a warning can be sent to the pilot to land for repair without threatening the integrity of the aircraft.

We designed a first muscle mock-up actuator to understand how redundancy of elementary actuator makes the ensemble resilient to damage (Perrier et al 2024). This mock-up made us learn a lot about hierarchical and multi-degree-of-freedom actuators. Notably, only few industrial applications exist for hierarchical actuators. We are currently working on designing a promising hierarchical actuator to would fit industrial requirements.

Project funded by (starting: january 2026).

(starting: january 2026).

Project funded by

(starting: january 2026).

(starting: january 2026).

Axis 2 : Pressurized cellular solids

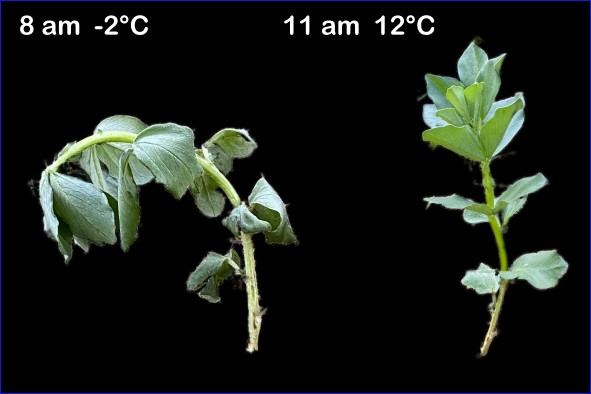

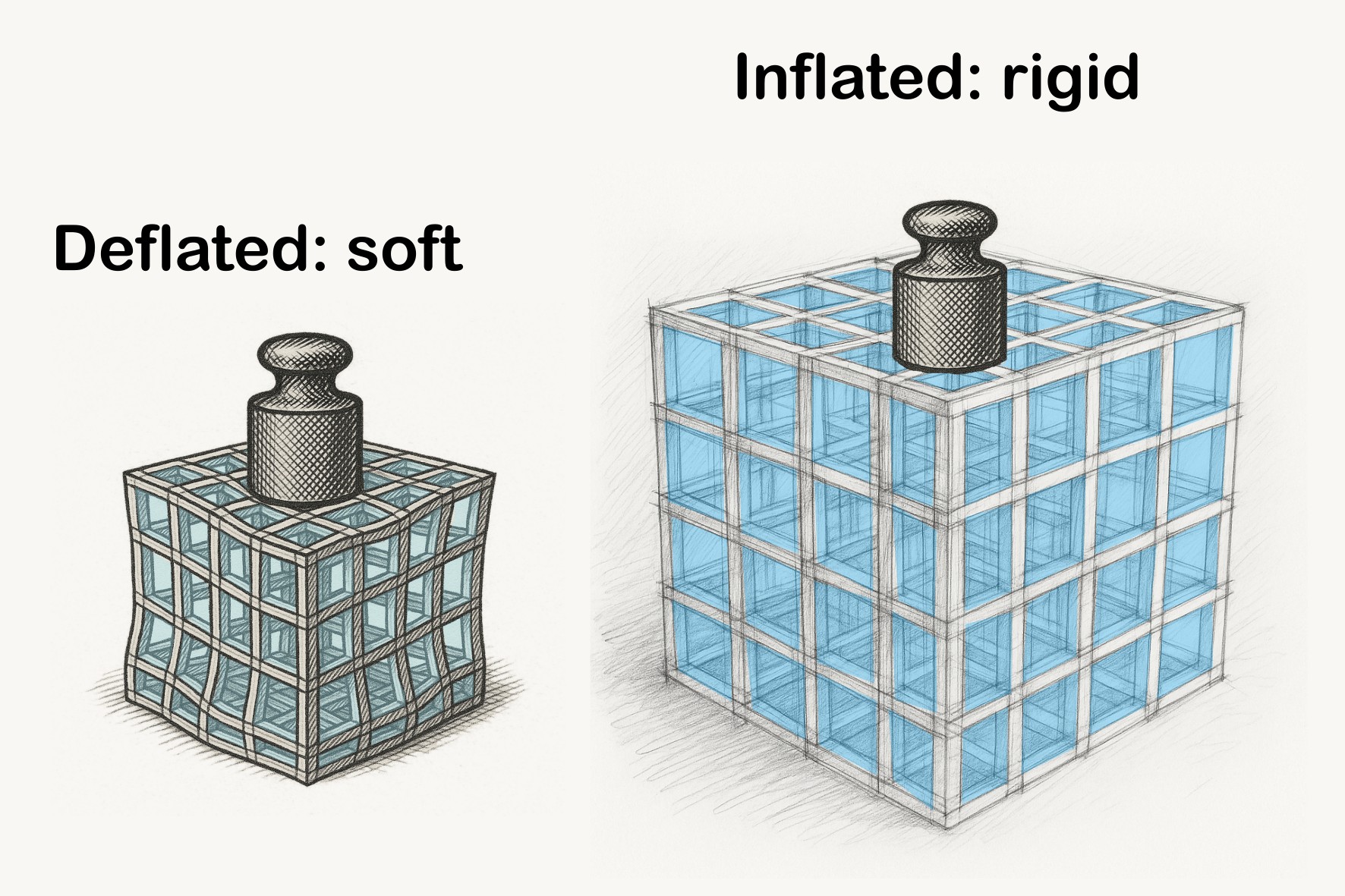

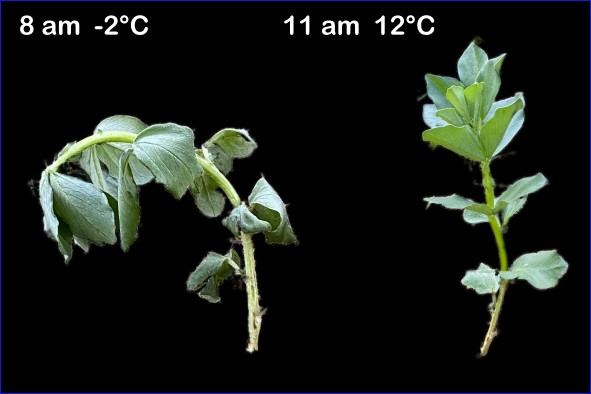

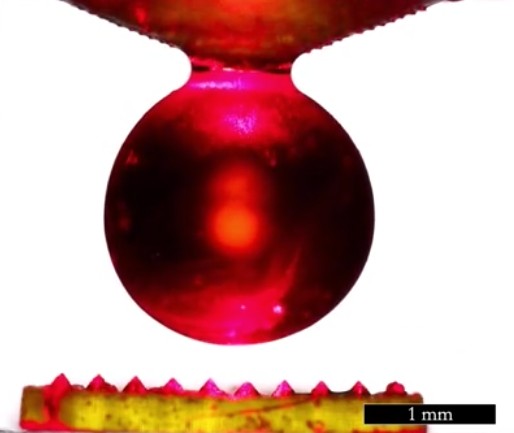

Turgor pressure modifies the mechanical properties of soft plant tissues. When the basil pot in the kitchen is left unattended for a few days: it wilts. But this process is reversible: as soon as the basil is watered, it perks up. The same phenomenon is observable on favea because of freezing weather (see picture).

Using Finite elements analysis and automated experiments on membranes , we showed that the change of mechanical propeties is a complex interplay between turgor pressure, cell geometry and cell wall material properties.

Inspired by the behaviour of soft tissues of plants, we want to create pressurized cellular material which macroscopic properties are controlled by the pressure of cells. We would be able to change material's rigidity, anisotropy and possibly auxetic behaviour, in a second.

Project funded by .

.

Using Finite elements analysis and automated experiments on membranes , we showed that the change of mechanical propeties is a complex interplay between turgor pressure, cell geometry and cell wall material properties.

Inspired by the behaviour of soft tissues of plants, we want to create pressurized cellular material which macroscopic properties are controlled by the pressure of cells. We would be able to change material's rigidity, anisotropy and possibly auxetic behaviour, in a second.

Project funded by

.

.

Plant soft tissues not only change stiffness, they are also able to create complex motions by pressurizing selective parts of the soft tissue. This is how a sun flower tracks sunlight (an example here).

We showed on a toy model (see figure) that complex motions could be achieved by changing the pressure pattern. More interestingly, we also observed that several pressure patterns would lead to almost identical motion. This is interesting for resilience : achiving a given motion can be done by multiple patterns, if a pattern comprises a deteriorated cell, then a pattern leading to a similar motion but not involving this cell can be used.

The challenge is now to turn this toy model into a useful resilient actuator for industry using for instance electro-osmosis .

We showed on a toy model (see figure) that complex motions could be achieved by changing the pressure pattern. More interestingly, we also observed that several pressure patterns would lead to almost identical motion. This is interesting for resilience : achiving a given motion can be done by multiple patterns, if a pattern comprises a deteriorated cell, then a pattern leading to a similar motion but not involving this cell can be used.

The challenge is now to turn this toy model into a useful resilient actuator for industry using for instance electro-osmosis .

Axis 3 : Leaves orientations as adaptation to climate change

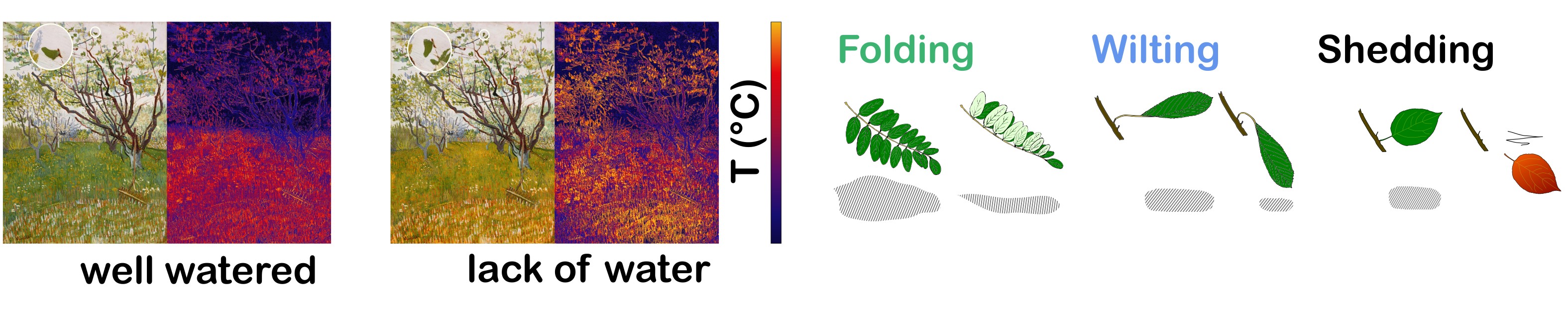

In drought periods, trees cannot afford sweating to cool down. Changing leaf orientation is an efficient water-free strategy to decrease leaf surface temperature by reducing the amount of light energy intercepted by one leaf. Measuring in-situ the evolution of leaf inclination angles will allow to refine (i) the transpiration rate of trees and the consequent embolism risk and (ii) the photosynthesis yield during drought.

Other research interests:

Leaf biomechanics

Microfluidics & Elasticity

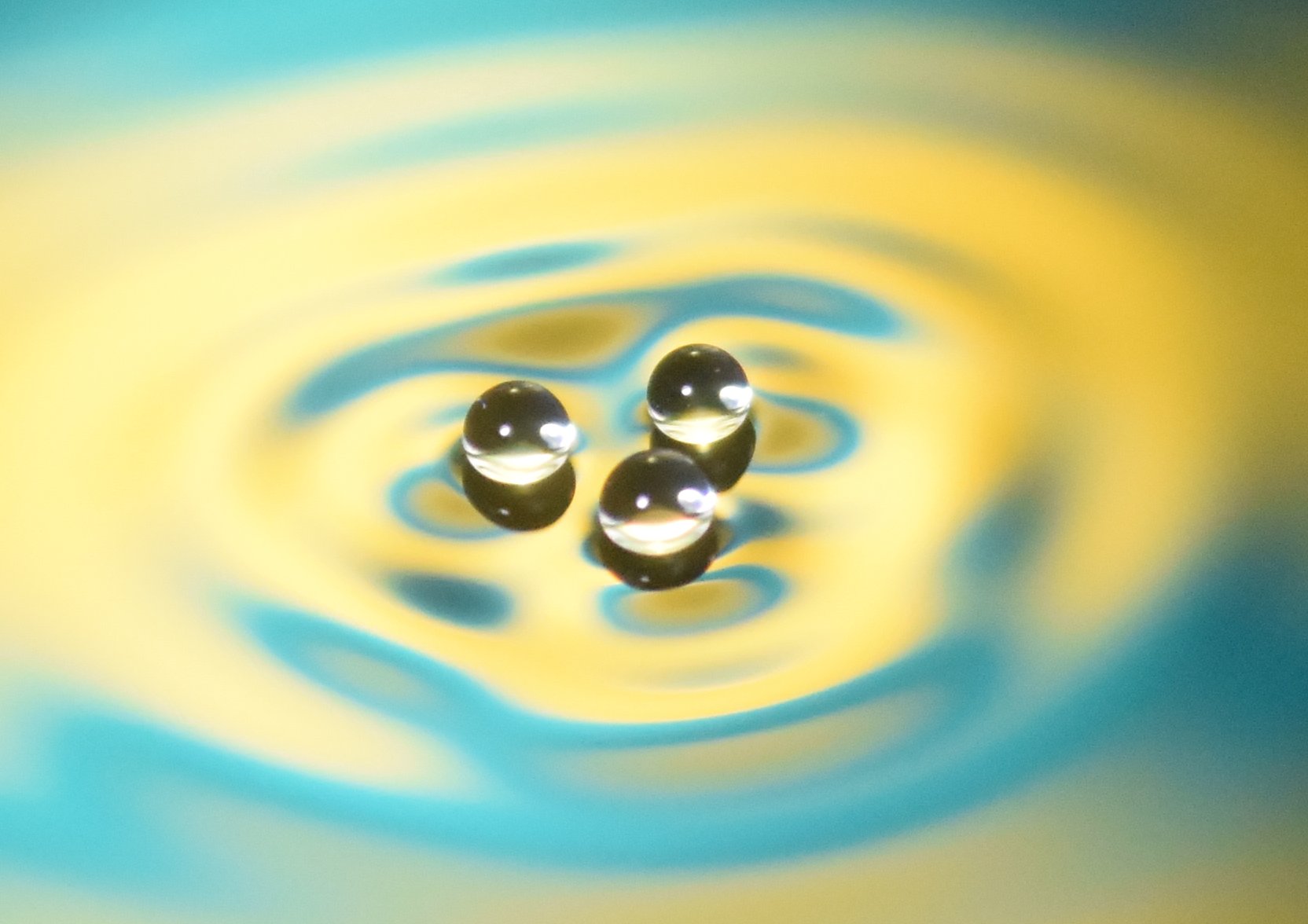

- Hydrodynamic quantum analogues (HQA)

- Capillary bridges

- Thin walls elasticity

- Pressurized membranes

Main collaborators (alphabetical order):

- Santiago Arroyave-Tobon

- Thomas Barois (CNRS)

- Julien Chaves-Jacob

- Baptiste Darbois-Texier (CNRS)

- Yoël Forterre (CNRS)

- Tristan Gilet (University of Liege)

- Jean-marc Linares

- Jan Pisek (University of Tartu)

- Marc Saudreau (INRAE)

- Stéphane Viollet

Research fundings

Principal Investigator (PI):

- 2022–2026 ANR, MExP (Machina Ex Pulvino), 319 k€

- 2022 Carnot Star, ChocCell: shock on neural cells, ≃10 k€

- 2022 PEPS INSIS CNRS, ChocCell: shock on neural cells, 17 k€

- 2021 PhD funding (Doctoral school 353), muscle mock-up, PhD student: R. Perrier

- 2021 PhD funding (CIFRE, Airbus Helicopters), fatigue lifespan of planetary roller-screw, PhD student: J. Lepagneul

- 2018 FNRS mobility, Tunelling effect for walking droplets, visiting scholar at MIT (Massachusetts, USA)

- 2017 Chargé de recherche (Junior researcher) at FNRS, Duo Corpora: interaction of walking droplets, FRS-FNRS, University of Liège, Belgium, 400 k€

- 2012 PhD funding (ASN), wind-foliage interaction, LadHyX, École polytechnique, France

Collaborator:

- 2024–2027 ANR ResiRob, PI: Stéphane Viollet (ISM, Aix-Marseille Université)

- 2023–2026 A*MIDEX Activ’Plant, PI: Yoël Forterre (IUSTI, Aix-Marseille Université)